- 您现在的位置:买卖IC网 > Sheet目录542 > 1-49935-0 (TE Connectivity)TOOL HEAD CRIMP 22-10AWG SOLIS

�� �

�

�

�SOLISTRAND*� and� STRATO-� THERM*�

�Crimping� Heads� Used� with� Double� Action�

�Battery� Powered� Hand� Tool� Kits� 1213804-� [� ]�

�Instruction� Sheet�

�408-10034�

�28� OCT� 10� Rev� B�

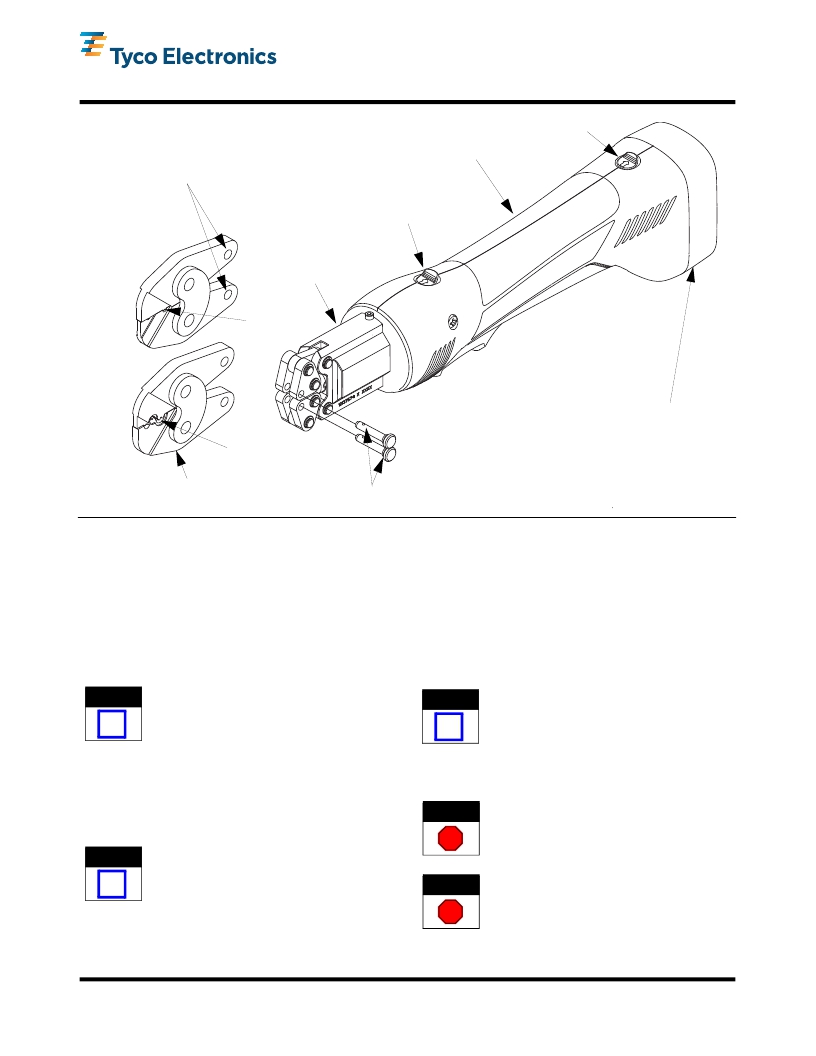

�Crimp� Head�

�Mounting� Holes�

�DAHT� Adapter�

�Assembly�

�2-Crimping�

�Chambers�

�Battery� Powered�

�Crimp� Tool�

�Retract� Button�

�Battery�

�Lock�

�3-Crimping�

�Chambers�

�Typical� DAHT�

�Crimp� Head� (Ref)�

�Quick-Release� Pins�

�Figure� 1�

�Battery�

�Cartridge�

�1725839-1�

�1.� INTRODUCTION�

�Crimping� Heads� 1-46447-0,� 1-69363-0� and�

�1-49935-0� are� designed� to� crimp� SOLISTRAND� and�

�STRATO-THERM� Terminals� and� Splices,� and�

�PLASTI-GRIP*� Terminals� and� Splices� onto� solid� or�

�stranded� copper� wire� size� 26-10� AWG.� Refer� to�

�Figure� 2.� The� crimping� heads� are� used� with� Double�

�Action� Battery� Powered� Hand� Tool� Kits� 1213804-[� ].�

�2.� DESCRIPTION�

�The� crimping� head� consists� of� integral� jaws� which�

�close� in� an� arc-like� motion.� After� an� operator� locates�

�the� terminal� or� splice� between� the� crimping� jaws� and�

�inserts� the� stripped� wire,� the� tool� is� activated� to� crimp�

�the� terminal� or� splice� to� the� wire.�

�3.� HEAD� INSTALLATION� AND� REMOVAL�

�NOTE�

�i�

�The� crimping� heads� can� also� be� used� with� the� 626�

�Double� Action� Pneumatic� Tool� Adapter� 1213563-1.�

�NOTE�

�i�

�Crimping� heads� are� coated� with� a� preservative� to�

�prevent� rust� and� corrosion.� Wipe� this� preservative�

�from� the� head,� particularly� from� the� crimping�

�surfaces.�

�NOTE�

�i�

�This� instruction� sheet� provides� recommended�

�procedures� for� wire� preparation,� crimping� head�

�installation,� crimping,� and� maintenance� and�

�inspection.� For� information� concerning� tool� setup� and�

�operation,� refer� to� Customer� Manual� 409-10056�

�packaged� with� the� battery� tool� kit.�

�Dimensions� are� in� metric� units� with� [inches� in�

�brackets].� Figures� and� illustrations� are� for�

�reference� only� and� are� not� drawn� to� scale.�

�Reasons� for� reissue� are� provided� in� Section� 8,�

�REVISION� SUMMARY.�

�3.1.� Installation�

�DANGER� To� avoid� personal� injury,� be� sure� to� exercise�

�extreme� caution� when� handling� the� crimp� tool.�

�STOP� Avoid� accidentally� depressing� the� trigger� control�

�when� installing� or� removing� crimp� heads.�

�DANGER� DO� NOT� operate� the� battery� tool� without� the� proper�

�crimping� head� installed.� After� crimping� head� is�

�STOP� installed,� make� sure� that� the� quick� pins� are� properly�

�inserted� to� avoid� personal� injury� and� damage� to� the�

�tool.�

�?2010� Tyco� Electronics� Corporation,� Berwyn,� PA� TOOLING� ASSISTANCE� CENTER� 1-800-722-1111�

�All� Rights� Reserved� PRODUCT� INFORMATION� 1-800-522-6752�

�TE� logo� and� Tyco� Electronics� are� trademarks.�

�*Trademark.� Other� products,� logos,� and� company� names� might� be� trademarks� of� their� respective� owners.�

�This� controlled� document� is� subject� to� change.�

�For� latest� revision� and� Regional� Customer� Service,�

�visit� our� website� at� www.tycoelectronics.com�

�1� of� 5�

�LOC� B�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

0010844061

084 DIA ASSY HDR HSG PIN 94V-0

0011020001

INSERTION TOOL HT1807

0011020003

INSERTION TOOL HT1353

0011030003

EJECTOR EXTRACTION TOOL HT1884

0011030016

TOOL EXTRACTION MOLEX .156 TERM

0011030022

TOOL EXTRACTION MOLEX .100 TERM

0011030036

TOOL HAND EXTRACTION

0011030043

TOOL HAND EXTRACT MICROFIT 3.0

相关代理商/技术参数

1499363

制造商:UNBRANDED 功能描述:INDICES MULTICOLOUR BLANK 10PART

1-499374-0

功能描述:集管和线壳 050 UNIV HDR SP 4S 30DP STD L2 RoHS:否 产品种类:1.0MM Rectangular Connectors 产品类型:Headers - Pin Strip 系列:DF50 触点类型:Pin (Male) 节距:1 mm 位置/触点数量:16 排数:1 安装风格:SMD/SMT 安装角:Right 端接类型:Solder 外壳材料:Liquid Crystal Polymer (LCP) 触点材料:Brass 触点电镀:Gold 制造商:Hirose Connector

14993741

制造商: 功能描述: 制造商:TE Connectivity 功能描述: 制造商:undefined 功能描述:

1-499374-1

制造商:TE CONNECTIVITY 功能描述:060 UNIV HDR SP 4S 30DP STD L2

1-499376-0

制造商:TE CONNECTIVITY 功能描述:

1499386-1

制造商:TE Connectivity 功能描述:CABLE,CAT5E,24UTP,CMP,1M,RL - Tape and Reel

1499389-1

功能描述:多配对电缆 CBL XG620 4/24 CMR WT 2.5 RL

RoHS:否 制造商:Belden Wire & Cable 线规 - 美国线规(AWG):18 对数:1 绞合:16 x 30 屏蔽:Shielded 长度:1000 ft 电压额定值:300 V 外壳材料:Polyvinyl Chloride (PVC) 绝缘材料:Polyethylene (PE) 类型:Audio, Control and Instrumentation 外壳颜色:Chrome

1499389-2

制造商:TE Connectivity 功能描述:TE640RF-GN05: CMR F/UTP 4/23 C6A 2.5K - Cable Rools/Shrink Tubing 制造商:TE CONNECTIVITY 功能描述:TE640RF-GN05: CMR F/UTP 4/24 C6A 2.5K